EXTICOV-LHD Special suffocating gratings cover

0,00 €

Fire suffocating cover for oil-filled electrical transformer pits

EXTICOV-LHD® suffocating gratings for concrete retention pits in electrical transformers respond to the risks of hydrocarbon pool fires in transformers. This anti-fire system, tested at the MFPA LEIPZIG (expertise -GU IV/99-01) and at the SP TRI BORAS (expertise of the technical research institute), complies with current French and international standards and laws, and allows pits to be rehabilitated by replacing the sufocating pebble bed in the transformer pit.

Description

Description

The EXTICOV-LHD® system is recommended for outdoor use and/or use with high levels of organic contamination:

- For recovery pits, fitted with fire-stop flaps, which communicate with either a fire-stop siphon or a remote pit directly.

- For so-called full retention pits, where at least 100% of the volume of oil potentially on fire will be in the retention pit

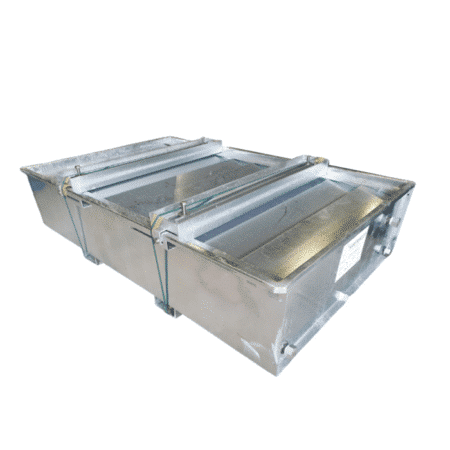

EXTICOV-LHD® roofing is made up of prefabricated, custom-made LHD® grating frames. The various elements are welded into panels. These are then installed at the top of the pit on specially designed angles, forming a 3-in-1 perforated structure floor: fireproof, slip-resistant and a handling area.

The EXTICOV-LHD® grating fire blanket owes its fire-retardant effect to the perforated structure of its surface, which allows only a reduced supply of oxygen to the source of the fire. EXTICOV LHD gratings are a former patented technology, specially designed to accelerate the passage of burning hydrocarbons into the pit under the gratings, even more quickly, consistently and effectively over time than “old” models of single, double-sloped or multi-sloped shutters.

Once the hot oils are “trapped” in the pit, the fire self-extinguishes almost instantly because the oxygen oxidant is not replenished. As the smothering process is very rapid, the temperature rise inside the pit is low and the thermal runaway that could accelerate the spread of the fire is rendered almost impossible. The device therefore acts passively and simultaneously on 2 of the 3 components of the fire triangle in a simple and effective way: temperature and the oxygen oxidant.

Description of the EXTICOV-LHD® standard range:

- Products tested several times in different independent laboratories (such as MFPA Liepzig or SP Technical Research Institute of Sweden or similar), with test report certificate in the name and property of the manufacturer, owned by the manufacturer and filmed by the laboratories.

- Technical characteristics: load of 500 daN/m² spread over 200×200 mm according to EN-14122 of 1.5 kN.

- Hot-dip galvanised steel with a recommended minimum thickness of 3 mm to guarantee a deflection of less than 4 mm in accordance with standard EN-14122.

- Additional surface treatment with GALVAGRID® zinc coating is possible for an anti-corrosion equivalent equal to or greater than C5H or C5X.

- Maximum permitted air passage of approximately 4.1% to ensure sufficient air tightness to prevent oxygen renewal under the pit.

- Diameter of perforation holes 7mm, approx 1065 holes per m², i.e. approx 4.1% of the surface is open.

- minimum flow rate of 660 L/min for mineral oil at a temperature of 90°C through 1 m² of cover.

- EXTICOV LHD anti-slip gratings in hot-dip galvanised steel, hot-dip galvanisation certificate to ISO EN1461-2022.

- As standard, the load-bearing capacity of the system recommended by our engineering team is 500 daN/m² (distributed load), equivalent to 2 operators and 1 200 L can of oil, but we can adapt this upwards or downwards to suit the customer’s needs and budget.

Accessories and options

The complete EXTICOV-LHD® system is made to measure for easy installation. On request, our SANERGRID or SONEC teams can visit your site to take measurements. Based on your plans or manual measurements, our engineering department designs and draws the system and its supporting structures. This enables us to offer some of the highest resistance per m² on the market. Please contact us for further information.

This range also includes a number of accessories to suit your needs:

- SPI filtration system, when the pit is outdoors to allow continuous drainage of rainwater; installation under the fire blanket using a concrete manhole attached to the pit.

- Non-slip access hatch for filters, SPI pre-filtration cages or simply access to the bottom of the pit.

- On request, we also work with stainless steel or GALVAGRID® for salt spray resistance equivalent to or better than C5H or CXS.

- MALT modules, for earthing using braids and lugs; please specify the section to be quoted.

Depending on the configuration of your project, we can offer you other EXTICOV-CCF single-slope flap fire blankets recommended for all types of retention pits, preferably indoors. (See Use and maintenance tab)

Technical data

Additional information

| Material | Aluminium, Stainless steel, steel |

|---|---|

| Conditions of use | indoor, outside |

| Fire resistance | YES |

Use and maintenance

The advantages of EXTICOV-LHD being supplied in custom-made frames mean it can be fitted to retention pits quickly and easily.

Their double-hole, opposed design avoids the fouling phenomena of “conventional” fire blankets consisting of a frame with shutters + gratings: impurities remain either less trapped on the blanket, or can be more easily swept or blown away, without the need for a major operation to dismantle the gratings to access the shutters. This is why a large number of electrical companies prefer to use EXTICOV LHD (3-in-1 gratings) outdoors and EXTICOV CCF (fire-resistant shutters + non-slip gratings) indoors, particularly when their collection pit is connected to a DEPOSIT concrete or prefabricated remote pit.

Finally, as EXTICOV LHD covers are delivered in welded panels, it is very easy to touch them up on site in the event of cables or soil rising up into the pit, and to make them airtight again quickly with cover sheets cut on site.

Before installing the cover:

Retention pits must be clean, smooth, free of pebbles or fire-retardant stones, free of hydrocarbons, re-cleaned or re-sealed. The walls of the pits and concrete blocks must be as flat and straight as possible, or be rendered, and capable of supporting the SPITFIX (not supplied, additional estimate required), the support angles and the weight of the frames and LHD gratings.

Installation of the cover:

- Position the angles at the correct height.

- Drill holes in the concrete where the pre-drilled angle holes will be, and fit the SPITFIX.

- EXTICOV LHD frames are delivered, assembled and identified using numbers which follow the numbering of the BPE drawing validated at the time of going into production. Position the frames as shown on the drawing.

- Earth the frames together if earth continuity is required (MALT KIT not included, request a quotation).

Maintenance of EXTICOV LHD suffocating grating covers:

Unlike EXTICOV-CCF flap-type fire blankets, EXTICOV-LHD fire-resistant grating blankets, because of their 3-in-1 grating frame design, require less maintenance. Nevertheless, it is still necessary to carry out regular visual inspections of the equipment in the following areas:

- Cleaning of organic materials (leaves, branches, moss, etc.) which may be positioned between the gratings and the shutters, and which could either leave the shutters permanently open, or block the passage of oil between the shutters. Depending on how dirty the site is, we recommend using a ballet, compressed air or high-pressure Kärcher.

- No missing or deformed EXTICOV LHD frames or gratings to let air through.

- Presence of CCF-STOP™, maintenance flap lockout screw.

- Integrity of the fire shutters, no deformation or damage (knocks, impacts, rust, etc.).

- State of ageing of the hot-dip galvanising protective layer and potential touch-ups.

- The frequency of these checks depends on the constraints of each site, depending on its degree of corrosion, dirtiness, presence of organic matter, etc.

Refer to the user manual for further details.

Failure to comply with good practice in use and failure to deal with anomalies and defects in the field are the responsibility of the owner of the equipment.

Additional information

Storage facilities for high-voltage substations in contact with polluting products must comply with the standards and laws in force.

Our EXTICOV-LHD natural extinguishing system is based on a design that has been tried and tested for over 40 years by the Danish manufacturer PCP, for which the SANERGRID Group is the exclusive representative in France. Originally developed for fire protection floors on offshore oil rigs, this technology has been used for over 40 years by electricity companies around the world.

EXTICOV-LHD® covers comply with the following legislation:

- NF C13-100 and NF C13-200, which prevent the risk of overcurrents and earthing problems. They protect people from direct or indirect contact with conductors, and electrical installations from the risks of fire, short circuits and lightning.

- NF EN 61936-1, relating to the design and installation of electrical installations, which requires a watertight retention tank representing 100% of the volume of oil used.

- NF C17-300, which deals with fire protection for electrical equipment containing dielectric liquids.

Several tests in specialist laboratories have confirmed the effectiveness of the EXTICOV-LHD® system:

- Tested at the MFPA LEIPZIG: expertise -GU IV/99-01 (Material Research & testing laboratory – Germany)

SP TRI BORAS tested: expert opinion from the Technical Research Institute (Sweden)