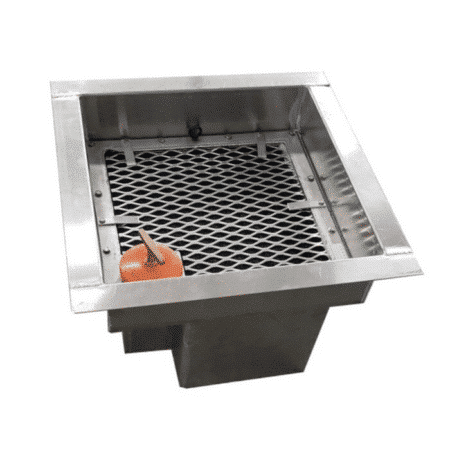

PETRO-BARRIER Hydrocarbon filter for drainage of large retention areas

0,00 €

Hydrocarbons separator catridge, built-in, long-life

The PETRO-BARRIER™ is a built-in filtration system for large volumes of hydrocarbon-contaminated rainwater for large transformer retention tanks and pits. Thanks to its self-locking system, it traps harmful hydrocarbons and thus prevents soil pollution. Its oleophilic and hydrophobic polymer component permanently traps hydrocarbons.

Description

Description

The PETRO-BARRIER™ is a system specially invented by SPI® in the 1990s for easy adaptation to all types of retention tanks and pits. It provides continuous filtration of drainage water for large volumes, while trapping harmful hydrocarbons: it therefore prevents soil pollution in accordance with EN 858-1 and the Water Act, with a discharge rate of less than 5ppm. It also complies with paragraph 471 of NF C13-200 (“All precautions must be taken to ensure that the recovery tank does not fill with water or that water is evacuated“). Our filters are regularly tested in independent laboratories, when new, in half-life conditions and after their recommended period of use (see Additional Information tab).

In the event of a major hydrocarbon spill, the component reacts and forms a plug, preventing any fluid from spilling into the environment. It is a self-locking system, operating without any mechanical parts or electrical connections.

The PETRO BARRIER™ is a product designed to adapt easily to your pit drains or at the outlet of a remote pit. It consists of a corrugated HDPE pipe that can be extended to the required reference in diameter and depth.

The PETRO BARRIER™ sinks or fits vertically at your low point of the contaminated water drain. The PETRO BARRIER™ is thus made up of 3 separate chambers:

- The upper part of the PETRO BARRIER™, through which fluids (water, dielectric oils or hydrocarbons) pass, known as the intake chamber, is made up of several filters and pre-filters to prevent clogging of the active part of the PETRO BARRIER™.

- The secondary chamber, or active anti-hydrocarbons filter, is made of aluminium. It is this cartridge that acts as the oil separator, and is made of a hydrophobic and oleophilic material that saturates and solidifies when in contact with oils and hydrocarbons, as well as natural or synthetic esters.

- The lower part, or evacuation chamber, collects the clean water at the filter outlet and evacuates it to your sewage system or directly into the environment. In all our tests over the last 30 years, the water leaving SPI filters has a hydrocarbon concentration of less than 5 ppm.

Once installed, the PETRO BARRIER™ must be covered with a special pre-filter made of steel grids and/or filter baskets to increase the water contact surface, and can be covered with clean crushed stones. Each of its parts plays an important role in water filtration.

When the PETRO BARRIER™ is installed in the pit: all retention surfaces are sloped towards the area where the PETRO BARRIER™ is installed for proper drainage of rainwaters. The installer must prepare the area as indicated and provide drainage holes for the barriers.

When the PETRO BARRIER™ is installed at the outlet of a remote pit (DEPOSIT or concrete type) or at the outlet of a BLOC CHICANE to ensure that the filtration of the ultimate traces of hydrocarbons is properly treated, it can be placed in a concrete or fibreglass manhole. This ensures that your sub-station does not release more than 5 ppm of hydrocarbons into the environment when leaving a retention pit or remote tank.

Finally, when you use the PETRO BARRIER™ at the outlet of a type 1 or 2 hydrocarbon separator, it ensures that in the event of a coalescing filter failure, your rainwaters are treated a second time in complete safety.

SPI filters have been recognised for over 30 years for their high reliability, extreme robustness and longevity, even in the most difficult conditions: resistance to hot transformer oils (>100°C), water emulsified with dielectric oil, high resistance to ultra-violet rays and thermal amplitudes, eco-designed to reduce the quantity of materials and CO2 during the manufacturing process.

Accessories and options

The PETRO BARRIER™ is available in a range of sizes to fit into existing sumps.

For specific flow rates or congestion, in particular large flow rates such as car parks, large HVB transformer pits or at the outlet of large hydrocarbon separators, we also recommend the STORM BARRIER™, which has an integrated bypass anti-overflow safety valve.

Contact us for more information.

Technical data

Additional information

| Material | Aluminium |

|---|---|

| Conditions of use | indoor, outside |

| Filtration | Dielectric oils, Hydrocarbons |

Use and maintenance

The PETRO BARRIER™ is installed either by casting it in concrete, or by inserting it in a concrete or fibreglass manhole in the pit, or at the outlet of a hydrocarbon separator, or at the outlet of a baffle block, or at the outlet of a remote transformer pit. There are many ways to configure the PETRO BARRIER™ and the locations of the latter. Finally, the PETRO BARRIER™ is available in several sizes, corresponding to different outlet flow rates

The PETRO BARRIER™ is available in a range of sizes to fit into existing sumps. The top filter basket attaches to the PETRO BARRIER™. The design of the PETRO BARRIER™ has been studied and optimised for over 20 years to facilitate maintenance and replacement operations. In particular, it is fitted with two flanges which, when installed, allow it to be removed and provide easy access to the various chambers of the PETRO BARRIER™ to clean it, replace the active cartridge or maintain it.

For your specific needs in terms of traceability and automatic reminders of your maintenance dates, SANERGRID® can set up a unit tracking system for you in return for a maintenance contract with one of our national partners.

Additional information

Part of the SPI® filter technology, the PETRO-BARRIER™ range is the European benchmark for hydrocarbon-contaminated rainwater filter cartridges for small-volume retention. It is the only filter on the market validated for over 30 years by the largest French and European industrial companies (EDF, ENEDIS, SNCF, SCHNEIDER, RTE, ABB HITACHI, SIEMENS, IBERDROLA, NATURGY, REE, EDP, ENEL, IREN, TERNA, E-ON, RWE, VATTENFALL, ELIA, ESB, SCOTTISH POWER, NATIONAL GRID, NETWORK RAIL, UK PN, BRITISH PETROLEUM, TOTAL ENERGIE, BASF, BAYER, ELES, CERN, ITER, VOLVO, DEUTSCHE BAHN, ADIF, SNCB, REPSOL, etc… non-exhaustive list).

Rainwater drainage and hydrocarbon pollution: thanks to the SPI anti hydrocarbons filter system, the tank is empty of water most of the time and ready to receive hydrocarbons. In compliance with water legislation, the water discharged from the tanks is not contaminated with more than 5 ppm of hydrocarbons, in accordance with standard EN 858-1 (“light liquid separation installations”).

SPI® filters are regularly tested by independent laboratories: SANERGRID Bureau Veritas report certified COFRAC I.D.: 003606/2776443/1/1/1 in 2015 (France), SPI Phoenix laboratory reports I.D.: AR67044 in 2002, 2004, 2005, 2009, 2018, 2022 (USA), TÜV report Nr 2432974 in 2016 (Germany), NUA report -Z-11895-1/1-2016.

Documentation

You may also like…

-

PETRO-BARRIER™ PTB-C-24 Internal filter exchange for PETRO BARRIER

0,00 € -

PETRO-BARRIER™ PTB-SF-24 Internal fine particle prefilter for PTB-24

0,00 € -

STORM WATER PETRO-BARRIER™ Hydrocarbon filter for high retention drainage

0,00 € -

PETRO-BARRIER™ PTB-DF-24 Internal coarse particle prefilter for PTB-24

0,00 € -

PETRO-BARRIER™ PUMP PTB-24 Anti-hydrocarbon filtration pumped system

0,00 €