PETRO-PIPE PIF-616 Mineral oil filter cartridge to slide into its housing

0,00 €

Hydrocarbon shutter filter to slide into its case, built-in, medium life

PETRO-PIPE PIF-616 is a mineral-oil contaminated rainwater filter cartridge to be inserted in its PIH-716 housing and embedded in the manholes of concrete retention pits on medium-sized transformers. Its self-locking system traps noxious particles, preventing soil pollution. Its oleophilic, hydrophobic polymer component permanently traps mineral oils.

Description

Description

SANERGRID‘s PETRO-PIPE PIF-616 is a cartridge specially invented by SPI® in the 1990s for easy adaptation to all types of retention tanks and pits. It ensures continuous filtration of drainage water, while trapping harmful mineral oils: it thus prevents soil pollution in compliance with EN 858-1 and the French Water Act, with a discharge rate of less than 5ppm. It also complies with paragraph 471 of NF C13-200 (“All precautions must be taken to ensure that the recovery tank does not fill with water or that water is evacuated“). Our filters are regularly tested in independent laboratories, when new, in half-life conditions and after their recommended service life (see Additional Information tab).

In the event of a major oil spill, the component reacts to form a plug, preventing any fluid from entering the environment. It’s a self-locking system, operating without mechanical parts or electrical connections.

Description of PETRO PIPE® PIF-616:

- Made of rigid PVC with UV protection for added strength and durability.

- Hydrophobic, polymeroleophilic component: permanently traps hydrocarbons

- Length: 45 cm / Diameter: 15 cm / Weight: 3 kg

- Approximate filtered flow (*): 16 L/min / Approximate saturation (*): 3 L / Recommended change (*): every 3 to 5 years

(*) Depending on site-specific conditions of use, such as the amount of traces of hydrocarbons filtered by the cartridge, regular maintenance of the tank/pit/prefilters, etc. Conditions of use for which SANERGRID® and SPI® cannot be held responsible.

For over 30 years, SPI filters have been recognized for their high reliability, extreme robustness and longevity, even under the most difficult conditions: resistance to hot transformer oils (>100°C), water emulsified with dielectric oil, high resistance to ultra-violet rays and thermal amplitudes, etc. SPI has ISO 9001 quality certification for its production process, and integrates an eco-design approach aimed at reducing the quantity of materials and CO2 during the manufacturing process.

Accessories and options

The PETRO-PIPE® range is the only one on the market to offer all references according to the use and type of pollutant: hydrocarbons, synthetic and natural esters or oils, etc. The choice of cartridge format also depends on the flow rate. The choice of cartridge format also depends on the flow rate.

- PETRO PIPE PI616-M2 for dielectric oils and hydrocarbons such as petrol, diesel, jet fuel, etc.

- PETRO PIPE PI616-FR3 for natural esters

- PETRO PIPE PI620-M2-SYNBLOC for synthetic esters

- PIFH-616 for mineral oils with in-concrete filters

- 2-inch valves and 2-inch elbows

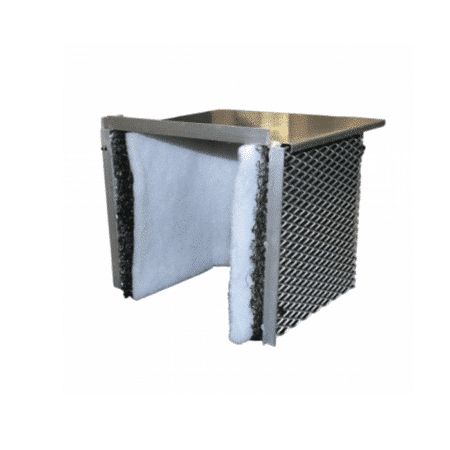

- External pre-filtration cages: PFB 810, 1012 or 1224 ranges

PETRO PIPE pre-filtration:

Pre-filtration is essential to limit the risk of clogging the P-PIPE cartridge due to dust in the water. Because it is used for permanent installations and large volumes of treated water, the PETRO PIPE range features 2 pre-filtration systems:

- Internal pre-filtration: All PETRO PIPE PI-616 and PI-620 are equipped with easily-cleanable and interchangeable internal pre-filtration foam: you don’t have to change cartridges systematically and simply clean the pre-filters. This reduces waste volumes and avoids the need for frequent cartridge replacement.

- SPI is the inventor of the external pre-filtration grid systems or PFB™ (ref. PFB-0810, PFB-1012, PFB-1224 ), developed in the 90s, which allow you to change only the active cartridge without having to change the whole system: only the filter cartridge needs changing when it’s saturated, you can change the internal and external pre-filters. Quick and easy to access, this system of pre-filtration grids also reduces maintenance on internal pre-filters.

PFB™ internal pre-filtration foams are cleanable and refillable on site.

Thanks to these two SPI innovations, you can reduce the amount of waste generated by more than 50% for an equivalent maintenance scope.

For special threads or substances, please consult us.

Technical data

Additional information

| Weight | 3 kg |

|---|---|

| Dimensions | 45 × 15 cm |

| Material | Rigid PVC |

| Conditions of use | indoor, outside |

| Filtration | mineral oils |

Use and maintenance

Installation of PETRO PIPE PIF-616:

- The filter is inserted into a previously drilled hole, or the sleeve is cast directly into the concrete. In both cases, the filter clamp is screwed to the sleeve flange.

- The use of special hydrocarbon-resistant sealants such as SIKA® around the sleeve/concrete contact is highly recommended to ensure consistent watertightness over time.

- An upstream valve is recommended to easily and safely set your retention volume before filter maintenance. For higher flow rates, a set of parallel or clarinet-mounted filters can be fitted.

- An optional PFB-0810 or PFB-1012 pre-filtration cage for PETRO-PIPE® can be installed upstream of the filter to remove impurities from the water and prevent the filter from clogging up too quickly. The PFB pre-filtration cage is always installed in the retention tank at the point where the water enters the filter.

Maintenance:

- SPI filters are sensitive to sludge and impurities carried by the water, which can considerably reduce flow or even block the filter. Good pre-filtration is therefore essential to protect the filter inlet, and must be checked regularly.

- The internal foams of PETRO PIPEs and those of the pre-filtration cage should be washed with clear water as often as required by the place of use, the frequency of rinsing depending on the quantity of impurities brought to each drainage point, and therefore on each industrial site.

- To keep track of your filters and replacement schedules, SPI products feature a batch serial number corresponding to the batch of active ingredient tested and validated by the manufacturer. So you too can trace your filters and recommended replacement dates by simple visual inspection.

- At end-of-life, the filter and pre-filter should be disposed of as conventional hydrocarbon waste under code [150202*].

For your specific needs in terms of traceability and automatic reminders of your maintenance dates, SANERGRID® can set up unit tracking for you, in return for a maintenance contract with one of our national partners.

Additional information

As part of the SPI® filter technology, the PETRO-PIPE® range is the European benchmark for hydrocarbon-contaminated rainwater filter cartridges for small retention volumes. It is the only filter on the market to have been validated for over 30 years by leading French and European industrial companies (EDF, ENEDIS, SNCF, SCHNEIDER, RTE, ABB HITACHI, SIEMENS, IBERDROLA, NATURGY, REE, EDP, ENEL, IREN, TERNA, E-ON, RWE, VATTENFALL, ELIA, ESB, SCOTTISH POWER, NATIONAL GRID, NETWORK RAIL, UK PN, BRITISH PETROLEUM, TOTAL ENERGIE, BASF, BAYER, ELES, CERN, ITER, VOLVO, DEUTSCHE BAHN, ADIF, SNCB, REPSOL, etc… non-exhaustive list).

Rainwater drainage and hydrocarbon pollution: thanks to the SPI anti-hydrocarbons filter system, the tank is empty of water most of the time, ready to receive hydrocarbons. In compliance with water legislation, the water discharged from the tanks is not contaminated with more than 5 ppm of hydrocarbons, in accordance with standard EN 858-1 (“light liquid separation plants”).

SPI® PETRO PIPE filters are regularly tested in independent laboratories: SANERGRID Bureau Veritas certified COFRAC I.D. report: 003606/2776443/1/1/1 in 2015 (France), SPI Phoenix I.D. laboratory reports: AR67044 from 2002, 2004, 2005, 2009, 2018, 2022 (USA), TÜV report Nr 2432974 in 2016 (Germany), NUA report -Z-11895-1/1-2016.