TRT-LHD-MODULO Modular Fire-Protection Containment

0,00 €

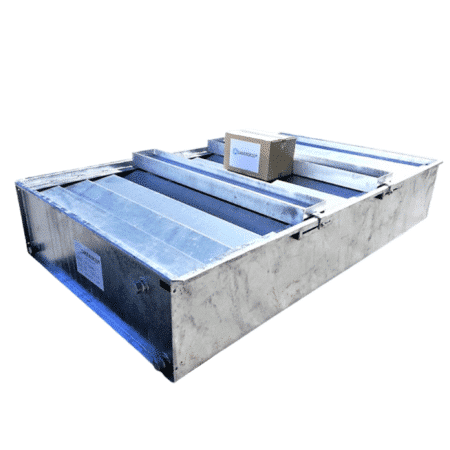

Modular Fire-Protection Containment for Power Transformers

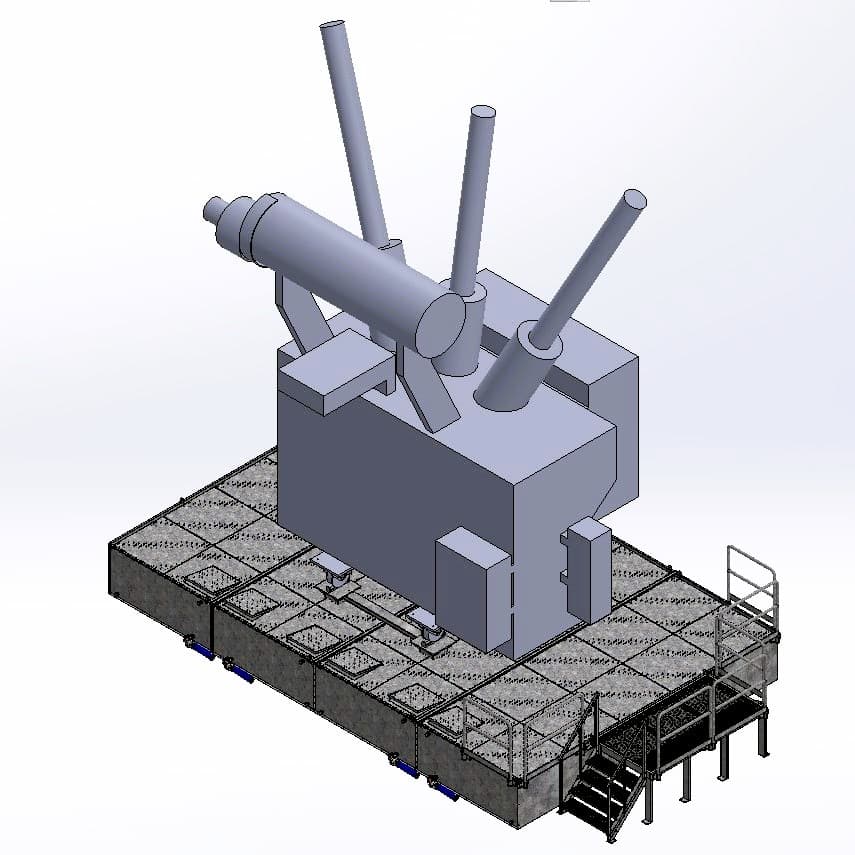

The TRT®-LHD®-MODULO range consists of multiple custom-made fire-protection containment units that interconnect in a modular system. SANERGRID®’s TRT®-LHD®-MODULO solutions ensure compliance with all regulatory and technical requirements for oil containment, fire protection, and hydrocarbon pollution control for large high-voltage power transformers, without incurring increased transportation costs.

Description

Description

The TRT®-LHD®-MODULO range enables the creation of large bunded areas and volumes for the containment of dielectric oils from your transformers.

Modular fire-protection bunds for large power transformers

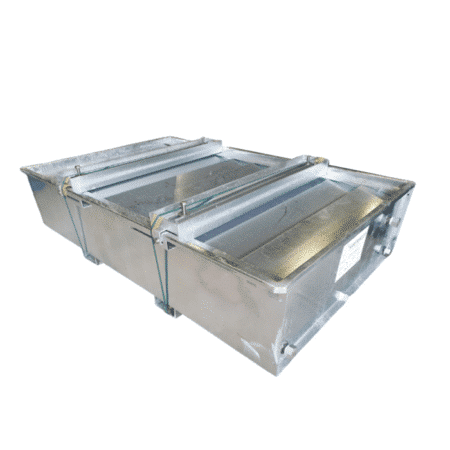

Thanks to an innovative and robust assembly system, the TRT®-LHD®-MODULO range consists of 2, 3, 4, 5, or “N” interconnected modules. Each module includes a TRT®-MODULO bund equipped with a fire-resistant grating cover EXTICOV®-LHD®, connected to the others via the SNG-Flow™ communicating vessel system, allowing fluid passage between bunds.

The TRT®-LHD®-MODULO range is recommended for large transformers when the bund’s width exceeds the European transport limit (2500 mm). This modular system allows the creation of extra-large bunds to accommodate high-voltage power transformers weighing over 300 tonnes and containing more than 100 tonnes of dielectric oil.

A solution for challenging civil engineering constraints

The TRT®-LHD®-MODULO system is also ideal for installations where on-site civil engineering is complex, outdated, or where excavating a concrete bund is not possible. Instead of a traditional concrete pit, the TRT®-LHD®-MODULO provides an above-ground bund installed on a reinforced, flat, and smooth concrete slab. This reduces civil engineering costs and significantly shortens the compliance timeline for electrical substations.

A fully compliant 4-in-1 retention system, installed in hours

With just a simple concrete slab, you can create a fully compliant bund system meeting all regulatory requirements:

✅ Containment: Retention of at least 100% of the dielectric oil volume, sized by our engineering team.

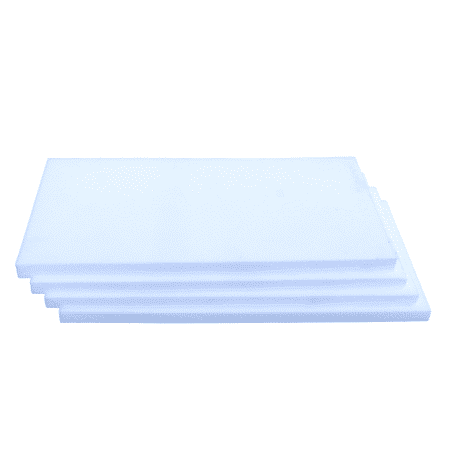

✅ Fire suppression: Hydrocarbon pool fire protection using the EXTICOV®-LHD® single-slope fire damper cover.

✅ Filtration: SPI® hydrocarbon-filtering drainage with PETRO PIT 416 or PETRO PIPE PI616M2.

✅ Personnel safety:

- Anti-slip electro-forged grating (30×30) or fully welded CUBE grating, supporting 500 daN/m² (2 operators + refill drum).

- SANERFALL™ guardrails, MODESCA™ staircases, and PLATABUND™ access platforms for secure operation.

Key features of the TRT®-LHD®-MODULO fire-protection bunds

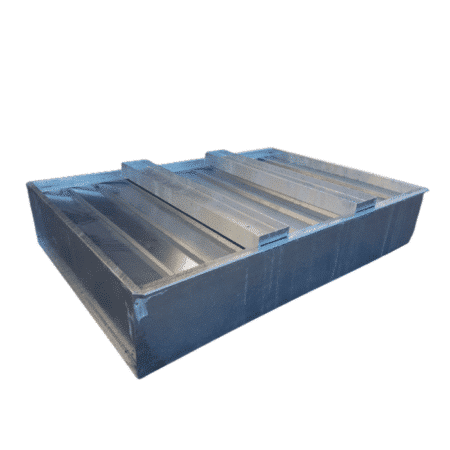

- S235 steel tank, 3, 4, or 5 mm thick, with hot-dip galvanisation certificate ISO EN1461-2022.

- Inter-bund covers with fastening clamps, bolted bund connections, and SNG-Flow™ sealed fluid passages with gaskets, washers, and installation keys.

- Fully sealed double welding on all retention areas, with individual quality inspections before leaving the factory.

- Fire suppression system (EXTICOV®-LHD®) with independently tested fire damper panels.

- Equipment support structures designed for easy installation:

- Fixed beams along the length or width of the bund.

- Adjustable beams, rolling rails, sliding beams, or multiple “elephant foot” supports with load-distribution plates, depending on the transformer’s positioning method (craning, sliding, or rolling).

Additional functionalities

- Two sealed wall penetrations for 1.5″ or 2″ quarter-turn valves, allowing:

1️⃣ Bund drainage

2️⃣ Connection of an SPI rainwater filtration kit - Standard configuration includes two sealed stainless steel plugs for unused penetrations.

- Integrated safety siphon at the bottom of the bund, ensuring excess rainwater drainage without oil discharge, even in the event of heavy rainfall or clogged filtration.

- Lifting hooks for easy unloading and on-site installation.

Built for long-term performance

The TRT®-LHD®-MODULO bunds are designed to match the lifespan of the power transformer or industrial equipment they protect, both for indoor and outdoor installations.

Accessories and options

The TRT®-LHD®-MODULO bund range for power transformers

The TRT®-LHD®-MODULO bund range is fully custom-designed, depending on whether the bund is used indoors or outdoors.

Please contact us with your transformer dimensions and/or transformer bay specifications.

This range also includes a variety of accessories, depending on your needs:

- PETRO PIT kit or PETRO PIPE kit for outdoor bunds to enable continuous rainwater drainage.

- SANERVIB-SP anti-vibration mounts.

- C5H anti-corrosion galvanic treatment: GALVAGRID®.

- Inspection hatch.

- Earthing system: MALT.

- Wheel locking brackets: SANERBLOCK™.

- SANERFALL™ guardrails.

- MODESCA™ access staircase.

- PLATABUND™ maintenance platform.

- Fixing and anchoring brackets for ground attachment.

- Rolling options on the bund: SANER-Rail, SANER-Grantex, and sliding system (for fixed beam configurations only).

- Option to move the modular bund with the transformer placed on top: MODULO-ROLL.

Technical data

Additional information

| Material | steel |

|---|---|

| Conditions of use | indoor, outside |

| Type of bin | fireproof, Modular |

| Beams | Adjustable, Fixed, Lengthwise, Widthwise |

| Fronts | Welded |

Use and maintenance

Pre-installation checks

- Ensure that the installation surface is smooth, flat, clean, and properly sized to support the weight of both the transformer and the TRT®-LHD®-MODULO bund.

- Verify that the load transfer alignment from the ground to the bund is correct, well-aligned, and appropriately dimensioned.

- If the bunds are stored outdoors, they must be regularly drained and should never be handled with water inside.

Installation of the bund

The bund must be unloaded using appropriate lifting equipment.

Installation by craning

- Position the transformer on the designated supports within the bund.

- Avoid vertical accelerations or transverse shearing forces during handling.

Installation by rolling or sliding

- If the transformer is to be rolled onto the bund or slid from the truck onto the bund, please contact us beforehand or refer to the SANER-Rail, SANER-Grantex, and sliding options.

Maintenance

Regular visual inspections must be carried out on the following points:

- Fire-resistant EXTICOV-LHD grating covers must be properly installed and securely fastened as per factory assembly.

- Sealing of wall penetrations, accessories, and/or plugs must be properly tightened.

- Integrity of the bund walls, ensuring no deformations, impacts, or corrosion.

- Condition of the hot-dip galvanisation layer and any required touch-ups.

- Proper rainwater drainage through filters:

- If clogged, clean the pre-filters.

- Replace filters if they are saturated or have exceeded their recommended lifespan.

- Sealing and ageing condition of the SNG-Flow™ communicating fluid system joints.

The inspection frequency depends on site-specific conditions, including corrosion levels, dirt accumulation, and organic matter presence.

Refer to the user manual for detailed guidance.

Liability

Failure to comply with best usage practices or neglecting to address site anomalies or defects is the responsibility of the equipment owner.

Additional information

Factory testing and compliance standards

As standard, all our first-series designs undergo factory testing known as type testing, accompanied by a comprehensive quality dossier, which includes:

- Weld integrity and sealing inspection certificates using penetrant testing procedures such as ARDROX 996 P2, PENTRIX 100, or equivalent, conducted by a third-party organisation.

- Critical dimensional inspection certificate post-welding.

- Hot-dip galvanisation certificate in compliance with EN-1179, with galvanisation thickness control in accordance with EN-ISO-1461, validated by a third-party organisation.

- Manufacturer’s material compliance certificate and pre-assembly inspection before shipment.

- Upon request, we can provide additional certificates, tests, or specific calculation reports.

Regulatory compliance

Our bunds comply with European Regulation EU No 548/2014, also known as ECODESIGN, implementing Directive 2009/125/EC, which establishes eco-design requirements for transformers with a minimum 1 kVA rating used in 50 Hz transmission and distribution networks or industrial applications. This includes:

- ECODESIGN Tier 1 (2015)

- ECODESIGN Tier 2 (2021)

They also conform to the following standards:

- French standards NF C13-100 and NF C13-200, which address risks related to electrical hazards, overcurrents, grounding issues, fire hazards, short circuits, lightning, and environmental pollution.

- NF EN 61936-1, covering the design and assembly of electrical installations, which requires 100% oil retention capacity, as well as pre-dimensioning guidance on bund volumes, surface areas, safety distances, fire protection systems, and rainwater management for outdoor hydrocarbon storage.

- CIGRE 23-07 and IEEE 980 recommendations, providing guidelines on fire barrier covers for transformer bunds and pits, as well as pre-dimensioning recommendations for both indoor and outdoor retention systems.

- EUROCODE 3, which governs the structural design of steel constructions for our bund manufacturing processes.

Factory and environmental certifications

Our manufacturing plants are certified under:

- ISO 9001 for quality management processes

- ISO 14001 for environmental management processes

All production facilities are located within Europe, ensuring shorter supply chains and reduced carbon emissions.

Rainwater drainage and hydrocarbon pollution control for outdoor installations

Thanks to the SPI hydrocarbon filtration system, the bund remains mostly empty of water, ensuring immediate containment of hydrocarbons.

In compliance with water protection regulations (Decree 77-254), the discharged water from the bund contains less than 5 ppm of hydrocarbons, meeting EN 858-1 standards (“light liquid separator installations”).

SPI® filters undergo regular independent laboratory testing, with certifications including:

- SANERGRID Bureau Veritas COFRAC-certified report (France, 2015) – ID: 003606/2776443/1/1/1

- Phoenix SPI laboratory reports (USA) – ID: AR67044 (2002, 2004, 2005, 2009, 2018, 2022)

- TÜV report Nr 2432974 (Germany, 2016)

- NUA report Z-11895-1/1-2016

(This list is non-exhaustive.)

Videos

You may also like…

-

ERT-F-W Extinguishing retention tank with widthways fixed beams

0,00 € -

TRT®-MODULO Modular retention tank

0,00 € -

EXTICOV-CCF Cover with special single-slope fire suffocating slats

0,00 € -

MALT Flexible earthing braids for electrical substations

0,00 € -

PTFE Teflon plates for electrical insulation

0,00 € -

ERT®-R Extinguishing retention tank with roll-on adaptation for transformers

0,00 € -

SANERBLOCK Locking brackets for transformer wheels

0,00 € -

ERT-W Extinguishing retention tank with width-adjustable beams

0,00 €