Galvanic corrosion protection

Hot-dip Galvanisation in High Voltage Substations

In high voltage substations, numerous metallic components are protected through hot-dip galvanisation. This technology coats steel with a layer of molten zinc, which solidifies to form a cathodic corrosion protection layer. The process is applied to structures such as HV towers, retention tanks, fire barriers, gratings, electrical towers and pylons, transformer radiators, and many other metallic components. It is carried out during manufacturing through immersion in molten zinc baths.

Durability of Hot-Dip Galvanisation

Hot-dip galvanisation provides durable corrosion protection, often lasting several decades in “standard” environments, as defined by ISO 1461:2022 and ISO 9223. These standards classify standard industrial outdoor environments (corrosion classes C3 or C4) as urban or maritime zones with low salinity. However, in more aggressive environments (classes C5, C5H, CX, etc.), where industrial pollution or salinity levels are high, the zinc layer degrades much faster. This reduces the lifespan of corrosion protection from decades to just a few years.

The GALVAGRID® Rust-Anode Primer Solution

GALVAGRID® Rust-Anode Primer revolutionises corrosion protection with a unique combination of technologies:

1. Advanced Galvanic Coating:

It provides an additional zinc layer that exceeds the thickness of standard hot-dip galvanisation, significantly enhancing the durability of metallic structures.

2. In-situ Recharging:

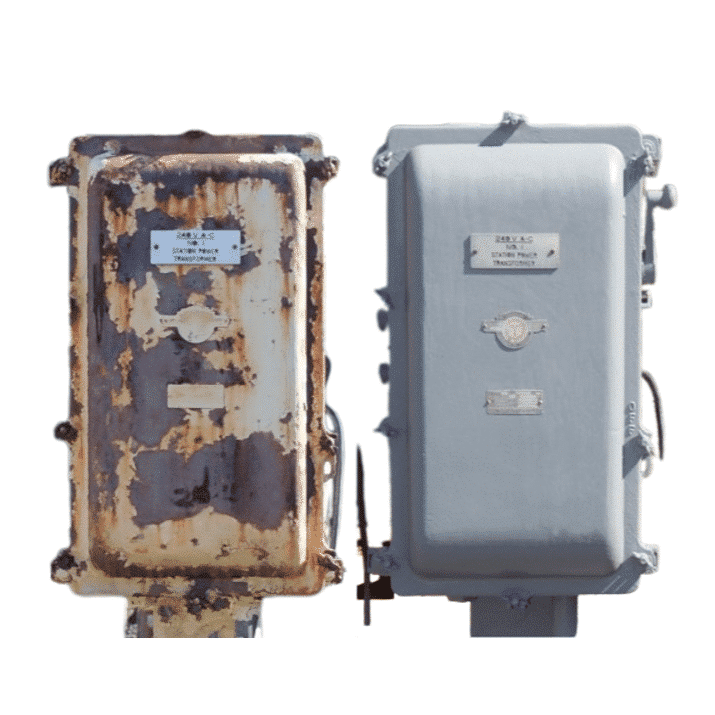

This allows restoration of already corroded metal structures directly on-site or in the factory, without requiring disassembly or replacement. This solution extends the lifespan of structures by 20 to 40 years.

This process, which can be carried out at ambient temperature, is suitable for both new structures and ageing equipment, offering an efficient and cost-effective alternative to traditional galvanisation.

Proven and Exclusive Development

The result of decades of research with NATO since the 1960s, GALVAGRID® Rust-Anode Primer benefits from over 50 years of proven experience. Now available to the civilian market, this technology is distributed exclusively by SYNERDIS® in Europe for industrial and electrical sectors.

Key Advantages

- Adaptability: Suitable for various environments, including the most corrosive (C5, C5H, CX).

- Cost-effectiveness: Avoids the expensive replacement of existing structures.

- Simplicity: Quick and flexible application, in factories or directly on-site.

- Exceptional Durability: Ensures a second life for metallic structures with enhanced resistance for decades to come.

GALVAGRID® Rust-Anode Primer is the ideal solution to tackle the growing challenges of corrosion in demanding industrial environments.

Showing all 2 results